Woodge System Update 25.03

We’re thrilled to bring you The Woodge 25.03 update, packed with nifty refinements and power boosts under the bonnet.

We’ve added locked and compressed manufacturing dates to give you precise scheduling control, streamlined task creation so only actionable items appear, and upgraded filters and Auto-Add logic for smarter workflows. The BluePrint tool now supports snapping and saved scenes to speed up your design process, while behind-the-scenes code cleanup delivers noticeable performance gains. We hope these improvements make your day smoother and more productive!

Locked Manufacture Process Dates

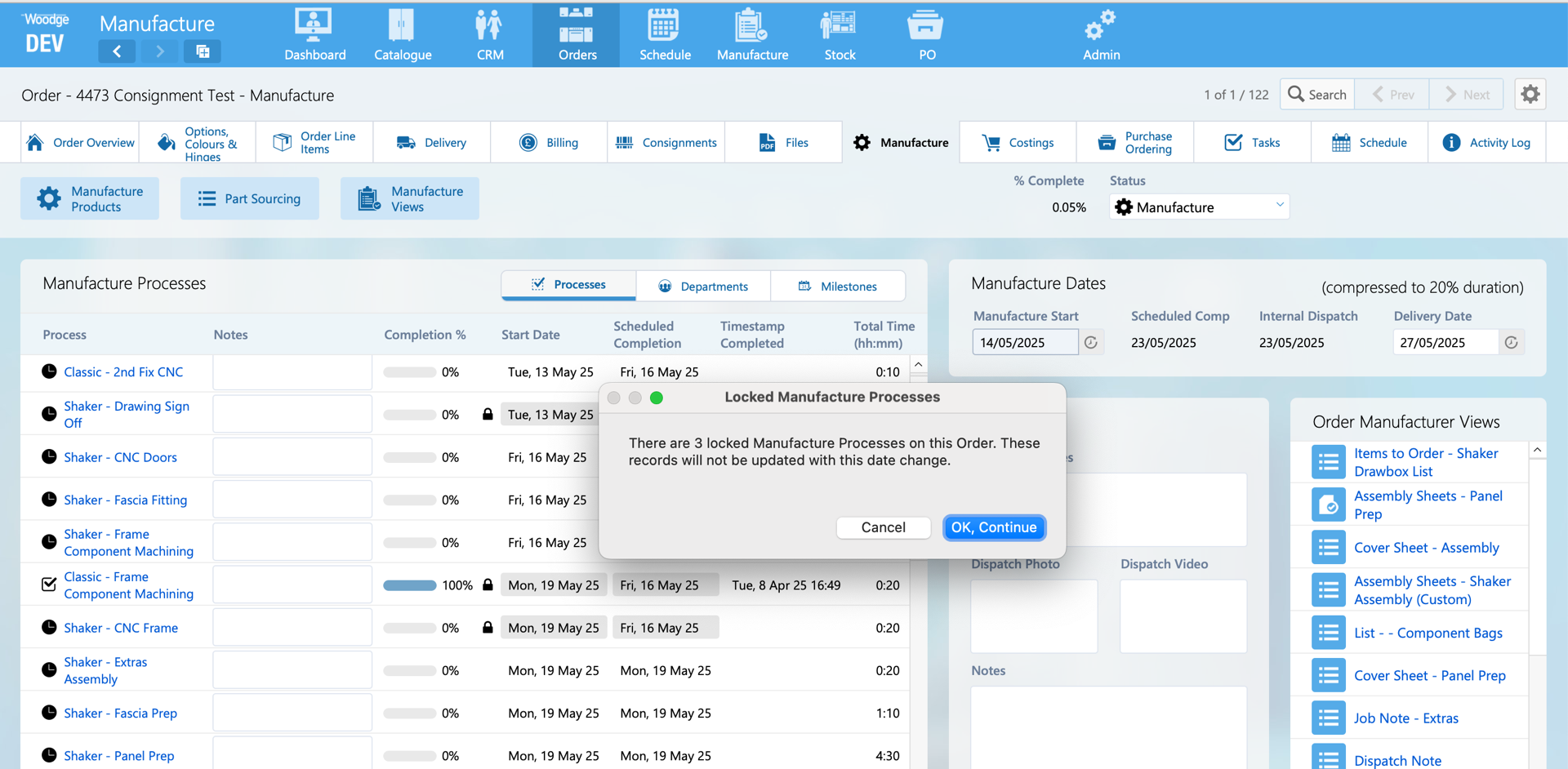

If a Manufacture Process Start Date or Scheduled Completion Date is modified, a padlock icon appears next to the dates, and they are shaded with a light grey background.

When the processes are recalculated, locked dates remain fixed.

If a date is changed on an order with one or more locked Manufacture Processes, you’ll be warned that those records won’t update. You can choose to Cancel or Continue anyway.

A Manufacture Process can be unlocked by clicking the padlock icon next to the date. You will be prompted to confirm that you want to unlock the date.

Once unlocked, the date remains at its modified value but will update the next time the schedule is recalculated.

Compressed Manufacture Process Duration

The duration of Manufacture Processes now compresses when the order’s overall manufacture duration is compressed.

In the example above, the process ‘Shaker – Cabinet Assembly’ has a 5-day duration.

When the order is compressed to 52% duration, the compression percentage appears in the ‘Manufacture Dates’ panel.

At 52%, the ‘Shaker – Cabinet Assembly’ duration becomes 3 days.

If an order is heavily compressed to 12% of its standard duration, the same process shrinks to 1 day.

The process ‘Shaker - Cabinet Assembly’ now has only 1 day duration.

The compression percentage is displayed in the ‘Manufacture Dates’ panel if it is less than 100%.

Template Task Creation

Templated order tasks are now only created when their parent task is completed. Previously, entering a status spawned every associated task at once, which could be overwhelming.

Now, if a task has ‘Hide Until Task Parent Complete’ set, it only appears once its parent task is finished—showing users only tasks they can actually complete.

Manufacture View Filter Improvements

The user interface for Manufacture View filters has been improved to handle large option lists more easily.

Popovers for selecting values (such as Process) now use a scrolling portal, with highlighted selections for clarity.

Popovers also support “type to filter,” making it quick to find items in long lists.

This functionality has been added to the filters: ‘Product Range’, ‘Product Source’, ‘Part Sourcing’, ‘Part Type’, ‘Component Type’, and ‘Process’.

Auto Add Product Improvement

The Auto Add Products functionality has been improved and now supports a custom calculation to determine if the system should process the rules.

For example, you can prevent auto-add rules from refreshing when an order is in ‘Manufacture’ status.

Improved Error Capture When Modifying Order Dates

When changing order dates, if the script encounters an error updating any records, you’ll see an error message and none of the records will update.

If the error involves an Order Milestone or Manufacture Process record, the message specifies which record type caused the problem.

Woodge BluePrint Tool Improvements

The Woodge BluePrint tool now supports saved Scenes within a design. A scene stores the visibility of line items and well as the camera position, type and render style.

To save a scene, adjust the camera and item visibility, click ‘Save Scene’ in the top right, name your scene, and click ‘OK’.

A new toggle on the left switches the panel between ‘Line Items’ and ‘Scenes’. Click a scene name to recall it.

To rename a scene, click its edit button, change the name in the dialog, and confirm. To delete, clear the name and confirm deletion.

You will be prompted to confirm that you want to delete the scene.

To update an existing scene, recall it, make your changes, then click the save icon next to the scene name. Scenes are stored with the design, letting you set up plan and 3D views for individual cabinets or rooms.

Scene information is saved with the design. This allow’s a views to be setup in plan and 3d for individual runs of cabinets, or rooms within the design.

Woodge BluePrint Cabinet Snapping

The BluePrint tool now supports cabinet snapping. When dragging an item close to a wall or another cabinet, it snaps into alignment. Cabinet dimensions (height, width, depth) are used so protruding elements like handles or sinks don’t interfere with snapping.

Wall cabinets automatically stick to the wall and will automatically rotate when dragged onto another wall. Items also snap to the corners or midpoints of other items for effortless alignment.