Woodge System Update 25.05

The Woodge 25.05 update introduces a range of improvements designed to make part sourcing, product variant management, and dimension updates more reliable and efficient. This release focuses on enhancing usability with clearer interfaces, better error handling, and new tools to speed up everyday catalogue changes.

New Part Sourcing Selection Interface

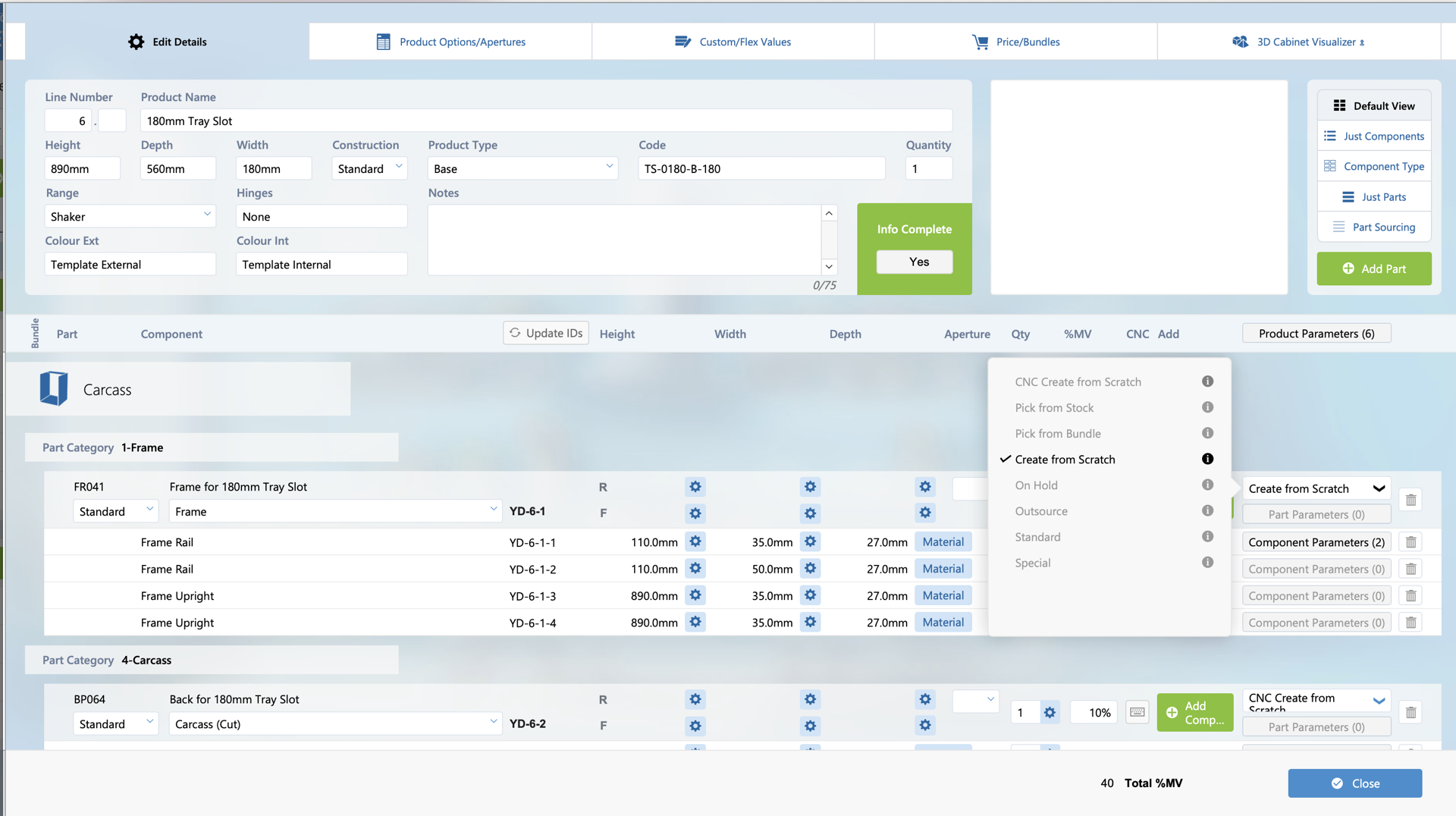

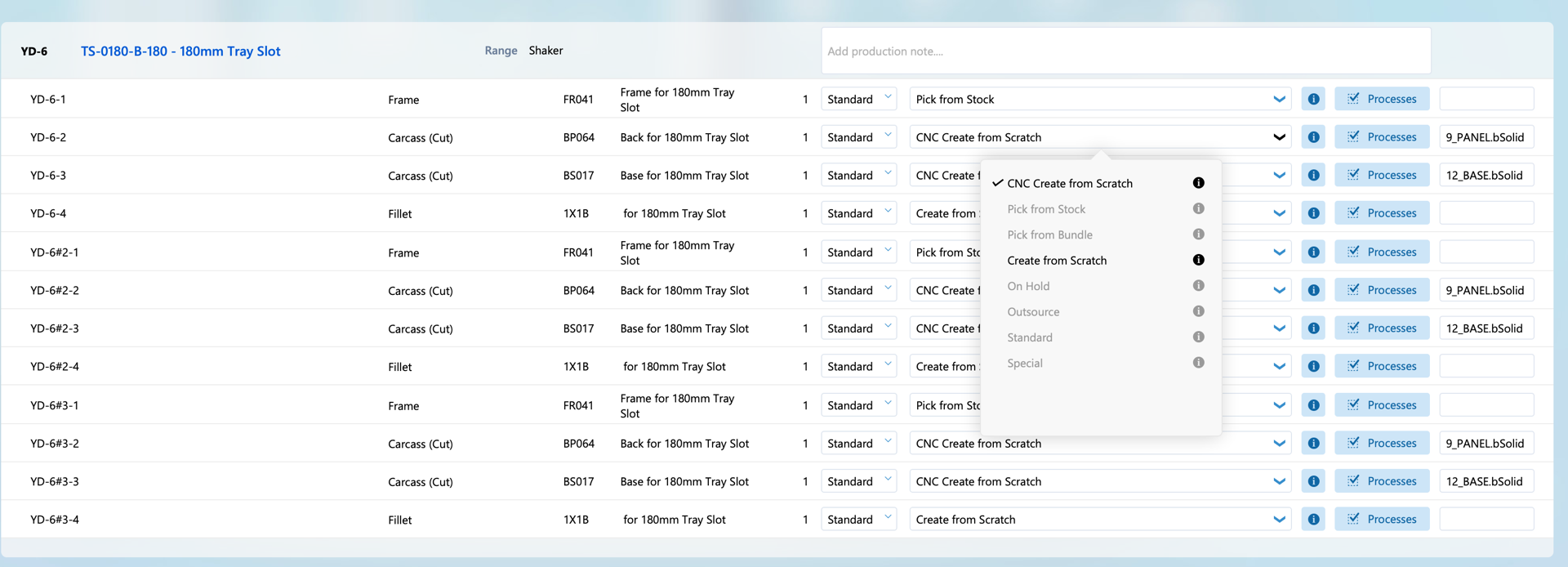

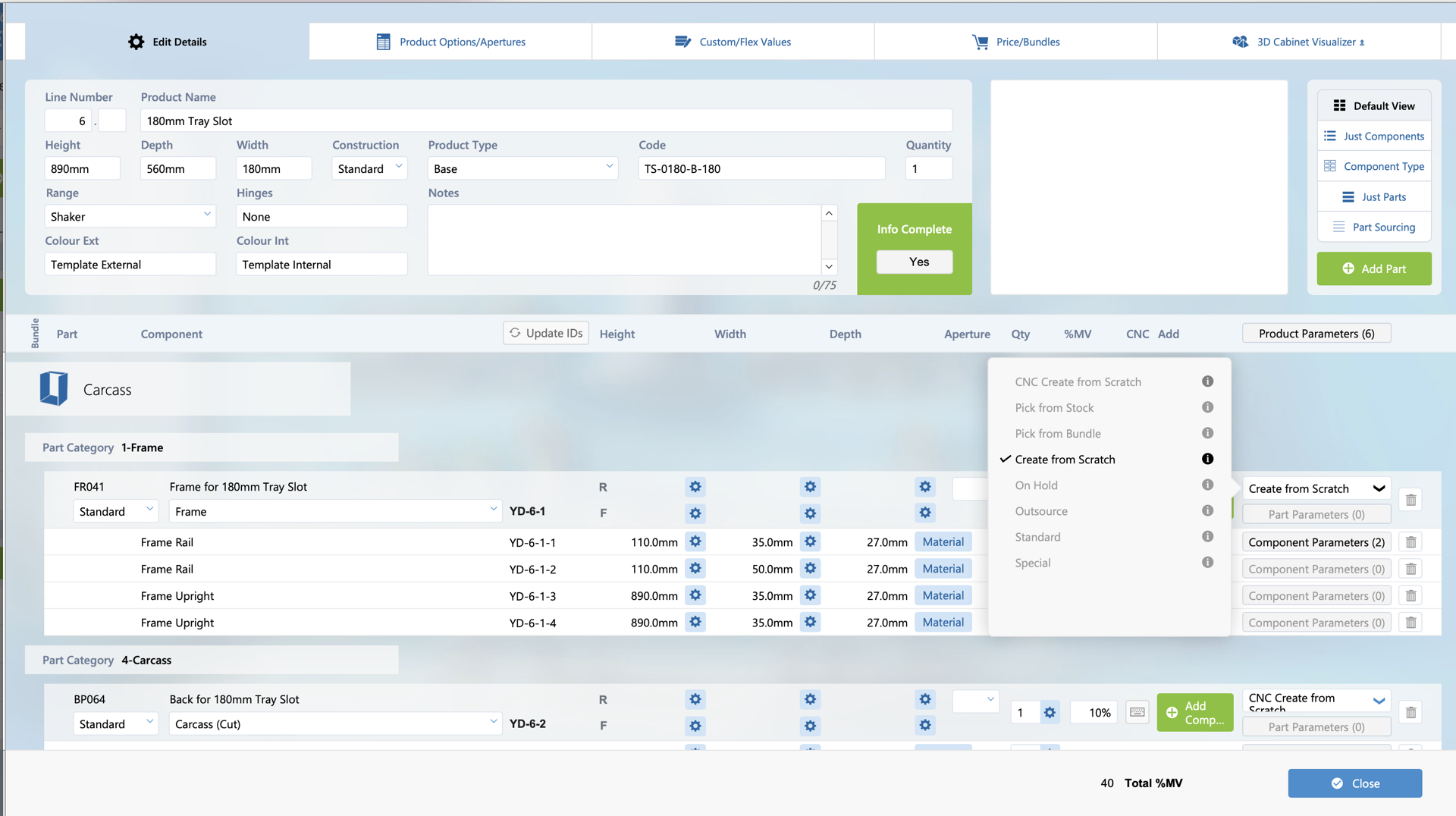

A new and improved user interface has been implemented for making Part Sourcing selections. Valid options are shown with black text, and greyed out options are Part Sources that are not valid.

This makes it much easer to pick a valid Part Source when making manual changes.

Hovering the mouse over the (i) icon will show the reason or reasons why a particular Part Source is not valid.

The same new functionality has been added to the Edit Card Window.

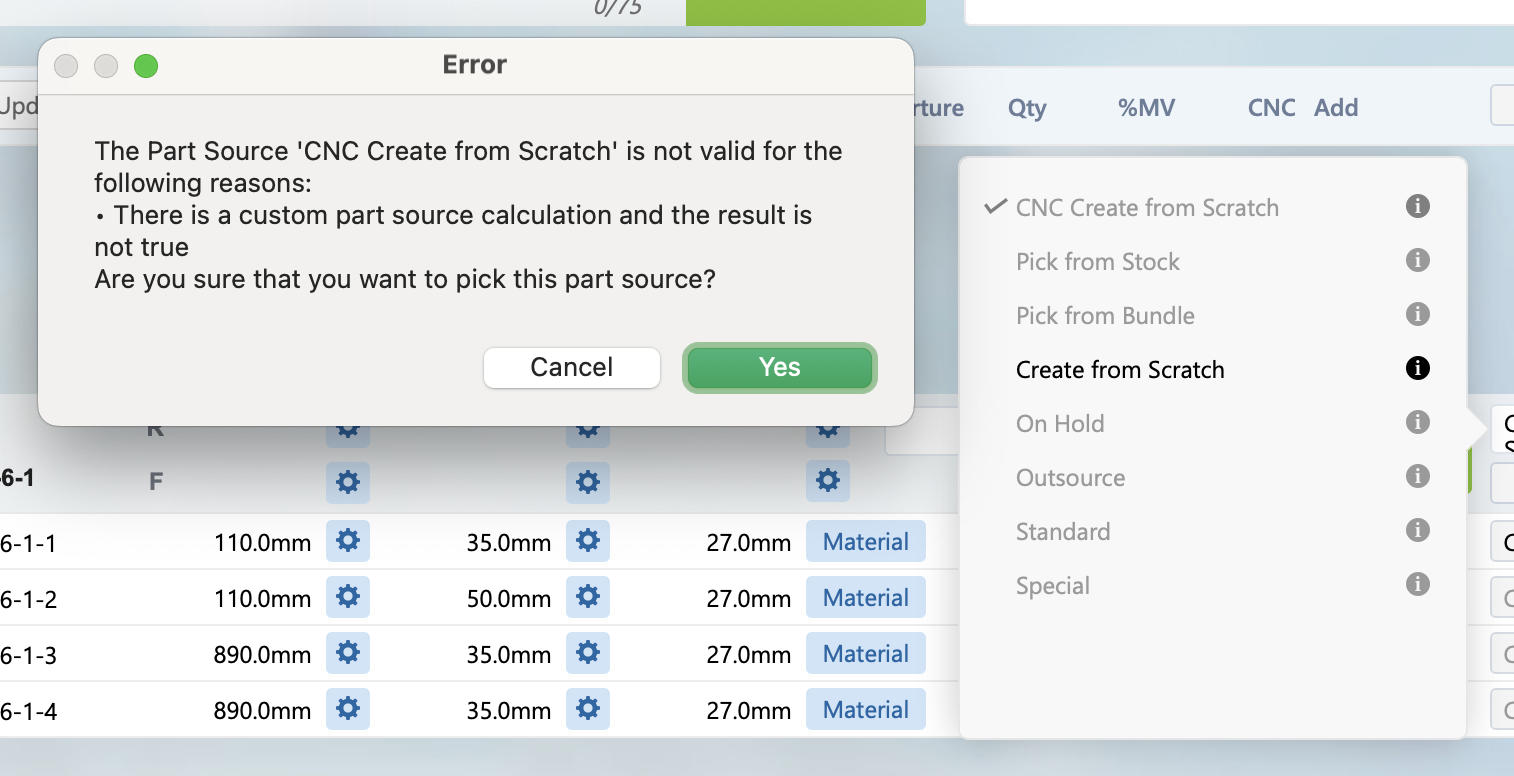

If a user tries to pick a Part Source that is not valid they are shown a dialogue with the reason it is not valid. They can choose to change it anyway or click ‘Cancel’ to revert the change.

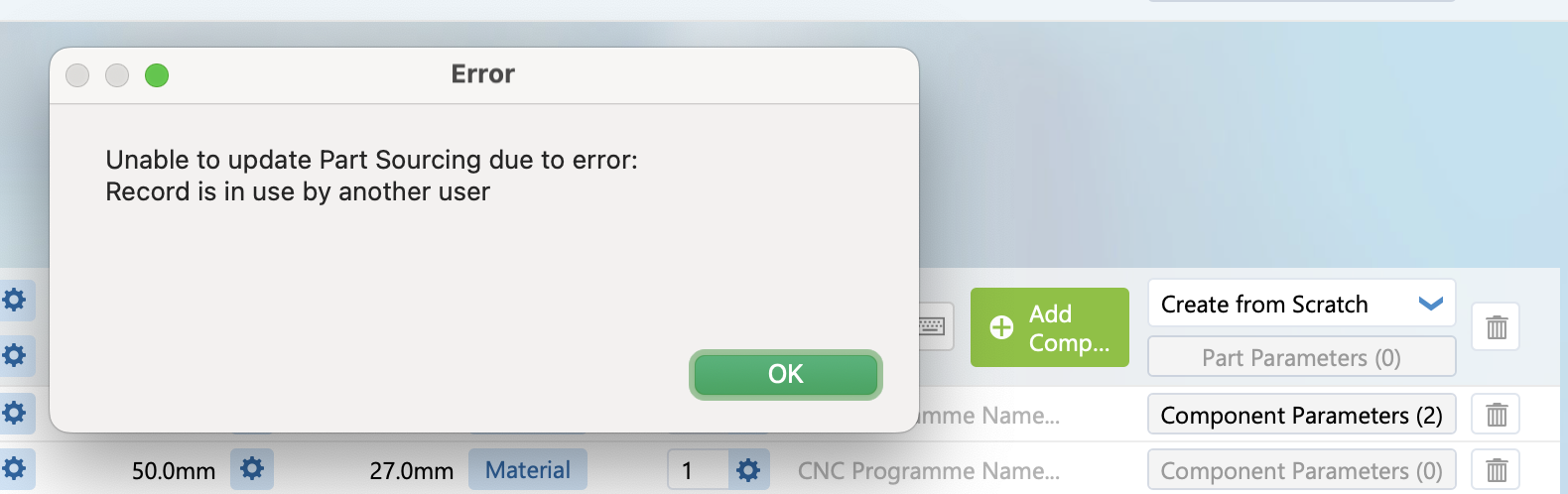

The Part Source change is now carried out as part of a transactional. If there are any errors with the update, the change is reverted and the user is shown an error message detailing the issue.

If the record is being modified elsewhere in the system, then the user can retry the modification again.

This ensures that are records are correctly updated at the same time.

Product Variant Improvements

The description of a product variant is now shown on the Product Detail view. This allows variants to have a more generic name and have more info in th description.

Product variant description can be set from the detail page.

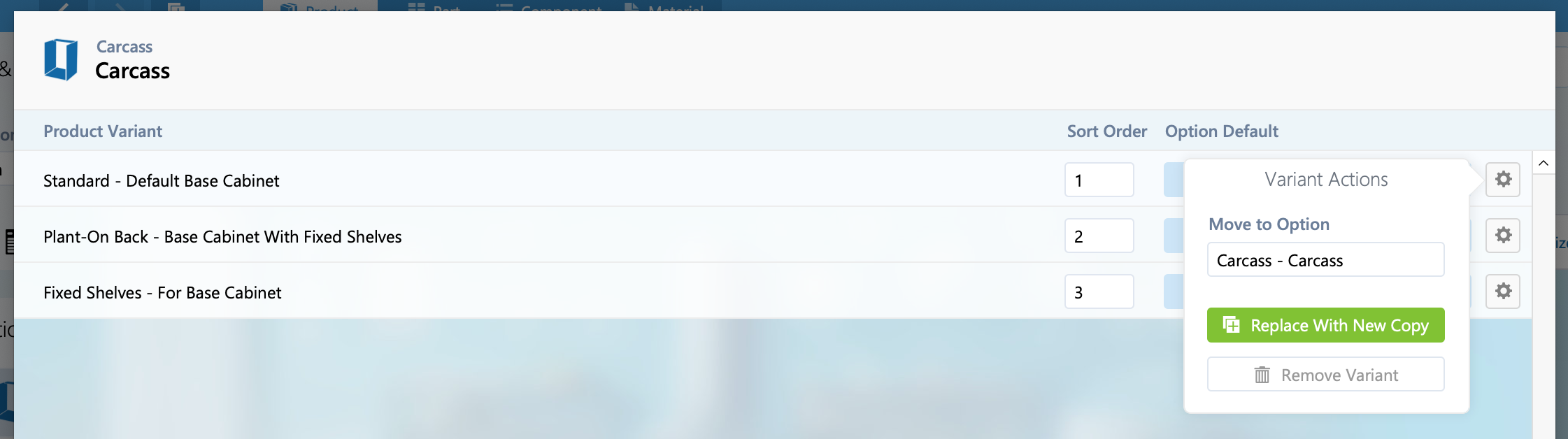

It’s also now possible to make a new copy of a Product Variant and replace the existing variant on a Product in a single step. Open the Variant card windo by clicking ‘Edit Variant’. Click the ‘Cog’ icon for the variant you want to replace, then click ‘Replace With New Copy’.

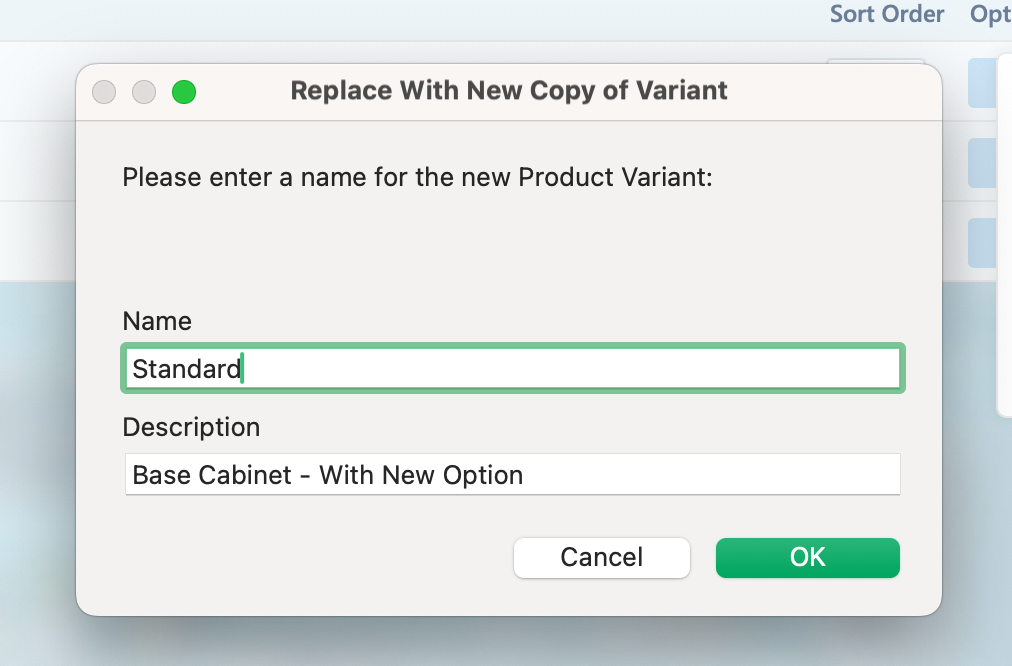

The user will then be prompted to enter a new Name and Description. The system will then duplicate the Product Variant including the links to Parts, Custom Values, Manufacture Parameters, Material Variants and Pricing Calculations.

The newly created variant will now replace the original Variant on the Product. This can make it significantly quicker to make catalogue changes.

It’s also possible to switch the default Product Variant for an option from the Variant card window as well. Simple click the blue checkbox button under ‘Option Default’ to make that variant the default for that option. This can be much quicker than closing there card window, opening the options window and making the change there.

Unreferenced Product Range CVs

A new feature has been added to ‘Show Unreferenced CVs’ for a Product Range. This can be accessed from the cog in the Range Custom Value panel. This will check through each Range CV and see if there are any references in any Component, Part or Product Variant dimension or quantity calculation.

If there any Unreferenced CV’s then the user will be shown a list of these. These can then be deleted if nessasary.

Product Dimension Updates

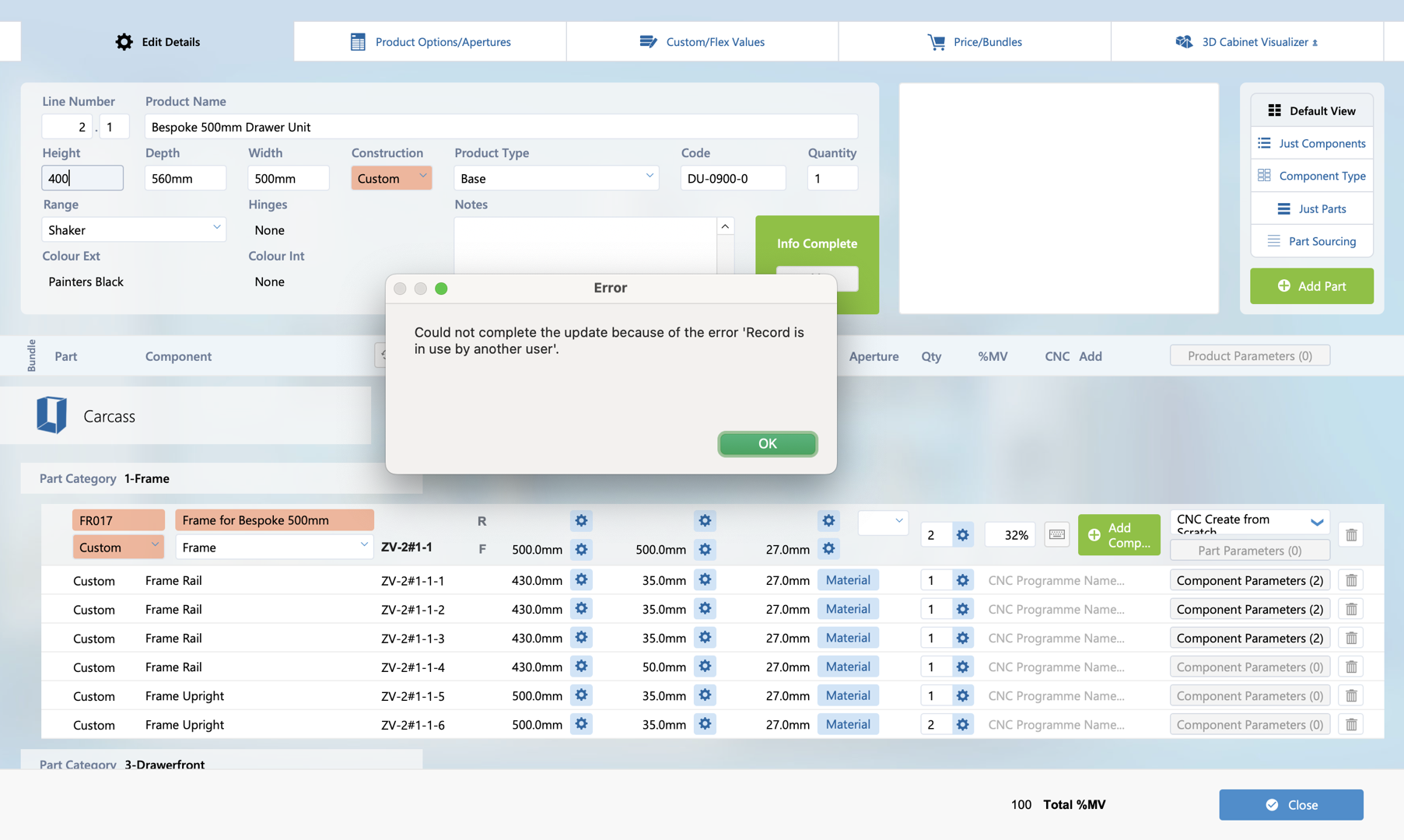

When a product dimension was modified it was previously possible to have some records not correctly update if another user was modifying one of the records. The system behaviour has now been updated so the user is prompted if the change was not able to be made.

If the update fails for whatever reason, the modified field will be reset to its previous value. This will ensure that the overall product dimension is always in sync with it’s parts and components.

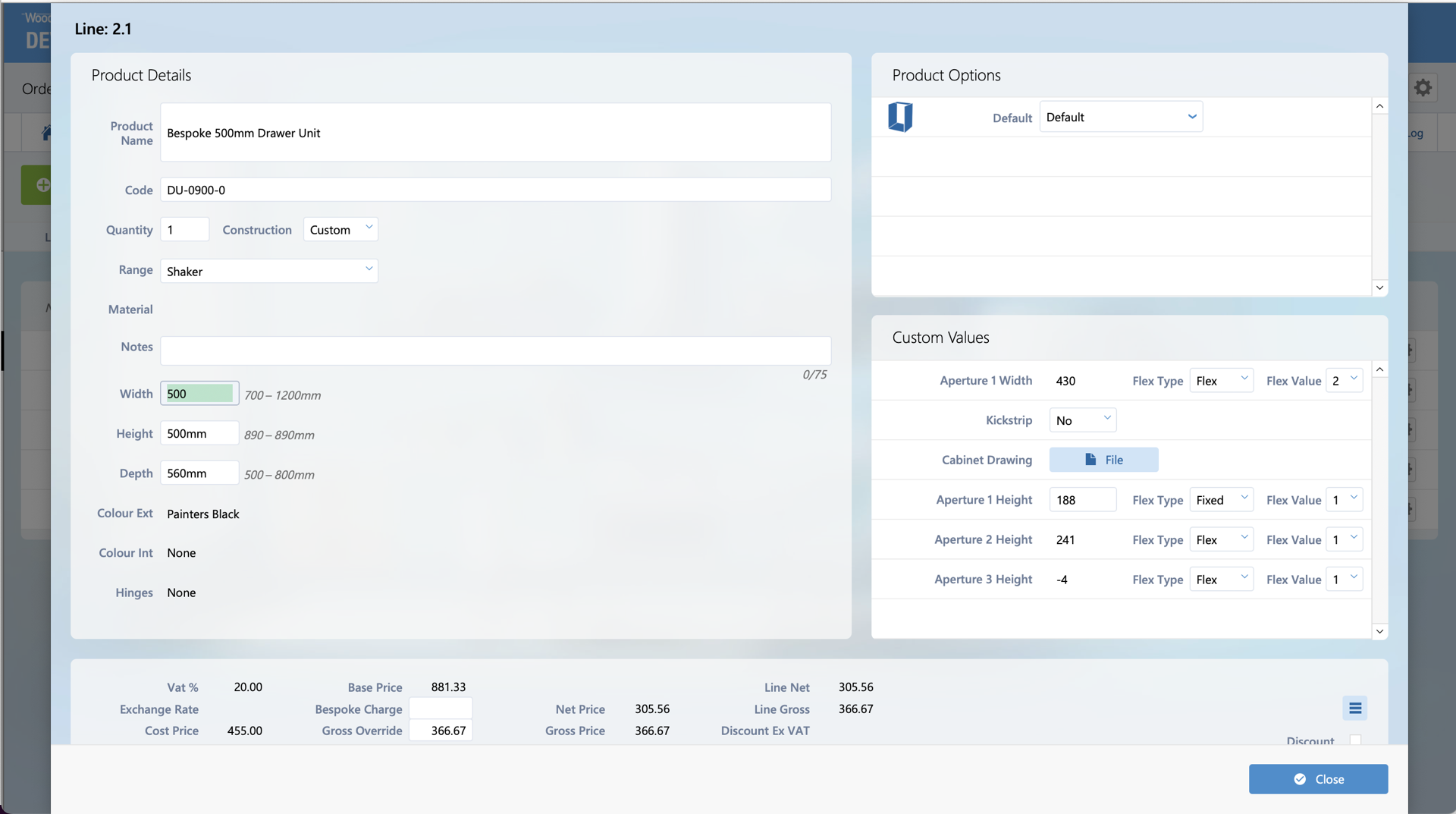

Any dimension changes made from the Lin Item window now correctly follow the same behaviour as changes made form the Edit Card Window. If any part Sourcing change are required these are now made immediately as part of the same transaction to ensure the correct part sourcing is applied if Part Construction is changed.